Printed for Profit: Choosing the Right 3D Printer Brand for Your Business. Our Story.

Share

Our Beginnings

Embarking on the journey of choosing the perfect 3D printer for your business is a path laden with twists and turns. I know because I've been there. Picture this: In early 2020, we launched 3D Print Land as a response to our collective 'stay-at-home' circumstances. Armed with a basic Creality Ender 3 Pro, we began our 3D printing adventure, blissfully unaware of the upgrades and transformations that awaited our trusty machine.

In those initial weeks, the Ender 3 Pro held its ground admirably, sparking our confidence to transition from hobbyists to entrepreneurs. However, as the days turned into months, the printer's true potential demanded upgrades. The laundry list of improvements included a Direct Drive Extruder, Auto Bed Leveling Sensor, and a suite of other enhancements, rendering our machine nearly unrecognizable from its humble beginnings.

-Micro Swiss - Direct Drive Extruder with Hotend

-3Dman 3D Printer Springs 10mm

-BL Touch Auto Bed Leveling Sensor

-Gwisdom 3D Printer Carbon Glass Heating Bed Platform

-Creality Ender 3 Silent Motherboard V4.2.7 Upgrade 32-bit Mainboard with TMC2225 Driver

-Creality Upgraded 4PCS Creality Aluminum Hand Twist Leveling Nut

-3Dman Upgrade 2020 Profile X-axis Synchronous Belt Straighten Tensioner

-Brand new Creality Official 3D Printer Wheels installed 12th May 2023

If you already have a printer and have used it for a while, you will gain a good understanding of what you want out of your next printer. You will find what is important to you and seek that out when you make another purchase. The money we spent on upgrades could have bought us a much better printer to start with.

A year and a half into running 3D Print Land with moderate success in the business, we owned 1 fully kitted out Ender 3 Pro, a second Ender 3 Pro with some upgrades, and a Creality CR10 V3 for larger prints with some of the same upgrades.

If you're looking for some quick advice about what the best upgrades for your printer are, then our favourites and the ones that made our life so much easier would have to be a bed levelling sensor and a Raspberry Pi for running OctoPrint or Klipper. This allowed us to not have to level the bed manually each time and using the Raspberry Pi, we could perform any function on the 3D printer remotely, see far more options, and use more plugins than possible without it.

This continued for the next year just using what we had. We don't get hundreds of orders a month so 3 printers performed more than well enough to fulfil our orders. When it came to upgrading this year we didn't do it because we needed more printers, now we were looking for ease of use, being able to print more materials, and most importantly, quality.

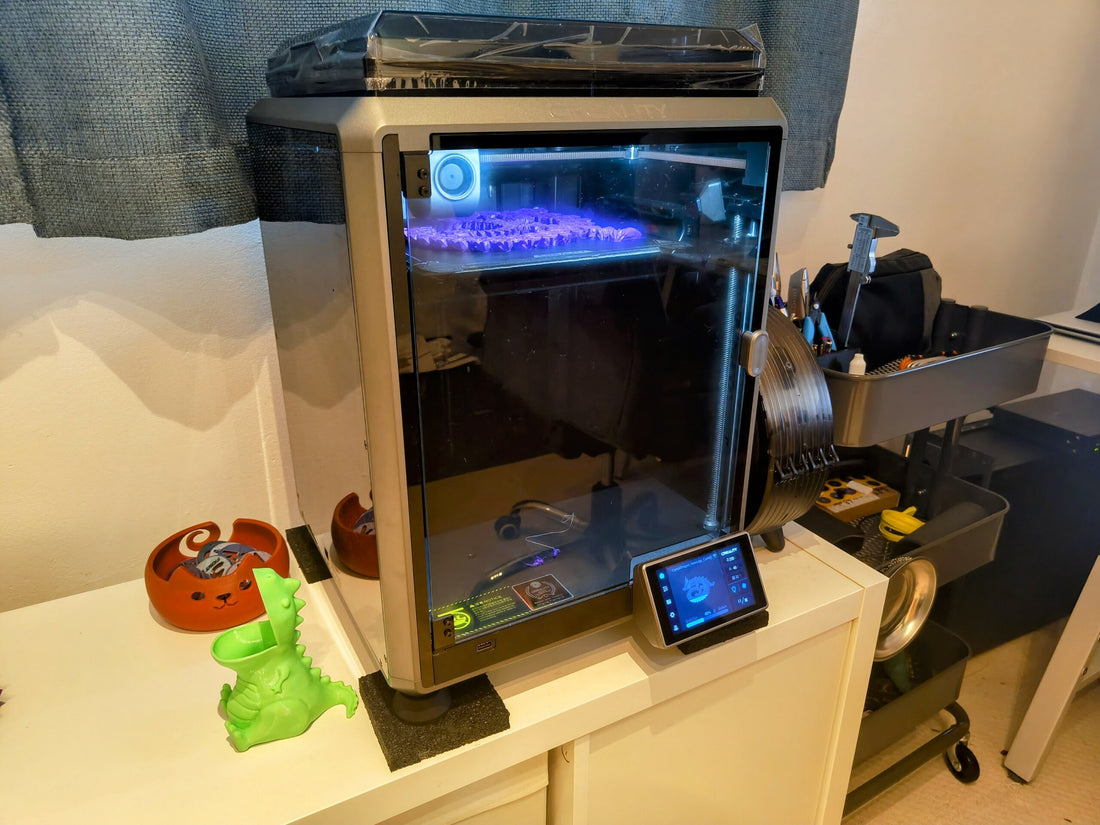

I just wanted to add that you should not buy the Creality CR-10 V3, it's a nightmare to level and work with. The image you can see was a very common sight and tedious work to deal with. The hot-end assembly is a pain to take apart and fix any problems.

The "Upgrade"

At first, our journey led us down the path of Creality's K1/Max 3D printers. We were excited about these models, considering them as the cornerstone of our growing 3D printing business. We even took advantage of a special offer on Creality's official website, snagging one of their latest premium offerings for approximately £530. Setting it up was a breeze, with only minor extruder issues to address.

After replacing the extruder with a genuine Creality part, we were eager to put the K1/Max to the test. The results were indeed impressive, meeting our expectations for both speed and print quality. We were content with our decision, believing that we had found our go-to 3D printers for the long haul.

However, our commitment to providing the best possible quality to our customers led us to explore other options. This exploration took an unexpected turn when we stumbled upon the Bambu P1P 3D printer. Intrigued by its reputation and user reviews, we couldn't resist giving it a try. What we discovered left us utterly convinced that we had found a new contender for our 3D printing arsenal.

The Bambu P1P not only surpassed our expectations but also highlighted the importance of considering more than just a printer's brand name. It became evident that ease of use in software and the sheer quality of the machine are pivotal factors in achieving outstanding prints consistently. Here are some of the reasons that ultimately swayed our decision in favour of the Bambu P1P:

- Software Experience: Bambu's slicer software proved to be remarkably intuitive and user-friendly. Creality's Cura fork left a lot to be desired. Auto orientation is an important feature for us. It makes the workflow...well...flow. This made it easier for our team to navigate the intricacies of 3D printing, resulting in fewer hiccups and smoother operations.

- Unrivalled Print Quality: The Bambu P1P consistently delivered pristine, high-quality prints, exceeding our expectations. Whether crafting intricate prototypes or fulfilling customer orders, the Bambu printer left no room for compromise.

- Reliability: We found the Bambu P1P to be exceptionally reliable, reducing downtime and enhancing our overall productivity. The consistency of its performance allowed us to meet deadlines with confidence.

- Support and Community: Bambu's dedicated customer support and the thriving user community were invaluable resources. Whenever we encountered an issue or sought advice, help was readily available, fostering a sense of camaraderie and problem-solving.

Conclusion

This revelation marked a turning point in our journey. We realized that the ideal 3D printer for our business wasn't determined solely by brand loyalty or a familiar name. Instead, it was defined by the machine's ability to seamlessly integrate with our workflow and consistently produce remarkable results.

While we were initially thrilled with the Bambu P1P, our journey uncovered some drawbacks that couldn't be ignored. These cons, while noteworthy, didn't significantly impede our progress, but they're essential to consider when weighing your options.

Limited Spare Parts Source: One notable downside of choosing Bambu is its exclusivity when it comes to spare parts. Currently, you can only purchase replacement components directly from their site. While their shipping times are respectable with an average delivery time of three days within the UK, it lacks the convenience of sourcing parts from platforms like Amazon, where you can often receive next-day or even same-day delivery.

Community Size and Experience: In the realm of 3D printing, community support is invaluable. Creality has an extensive and well-established community, particularly centred around its Ender series of printers. In contrast, Bambu is still relatively young in this regard, which means fewer user-generated resources and a smaller pool of shared experiences.

Open Source Plans: Creality has announced its intentions to go open source with the K1 line, paving the way for the community to modify and expand upon its offerings. While this plan hadn't materialized at the time of writing, it hints at potential future enhancements to Creality's 3D printers.

User Interface: The Creality K1's large touchscreen interface impressed us with its user-friendliness. Navigating the controls was swift and intuitive. In contrast, the Bambu P1P's interface, with its more conventional control scheme, felt somewhat dated and less responsive. The touchscreen experience is reserved for the pricier X1 Carbon model, which costs significantly more than the K1 without offering substantial advantages for our needs.

These factors didn't pose insurmountable challenges, but they did play a role in our decision-making process. In the end, we chose to part ways with our K1, opting to explore new horizons with a Bambu Lab P1S. This decision allows us to print ABS again and employ an AMS system for efficient filament swapping, as well as offer multi-colour printing options for our customers.

However, it's worth noting that Creality is rumoured to be considering similar enhancements in the near future, so the landscape of 3D printing technology is ever-evolving.

We hope to keep you up to date with our journey and what it might bring. Hopefully posts like this can help steer other small businesses in to making decisions that will ultimately help them grow and be successful.